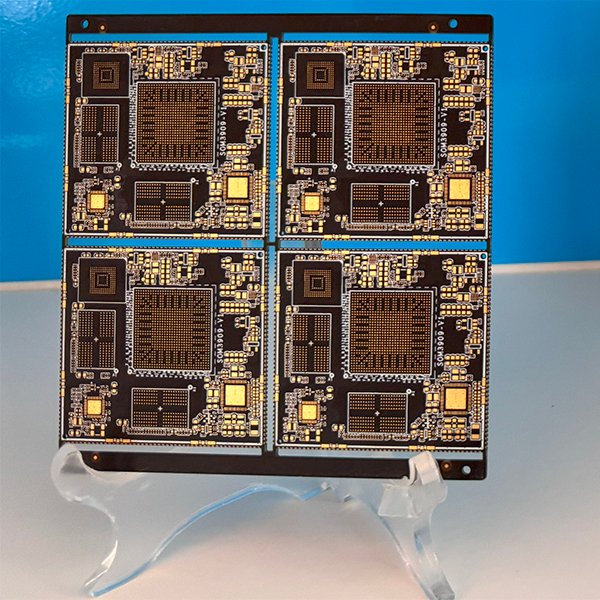

Advanced 20-Layer PCB for Aeronautical Communications

Advanced 20-Layer PCB for Aeronautical Communications

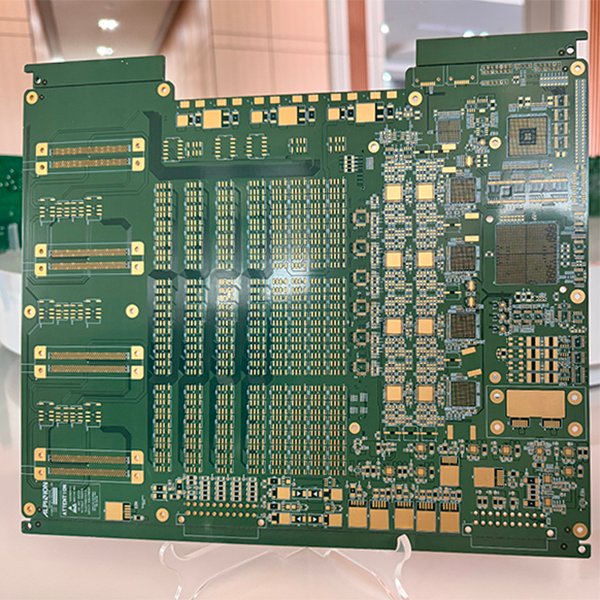

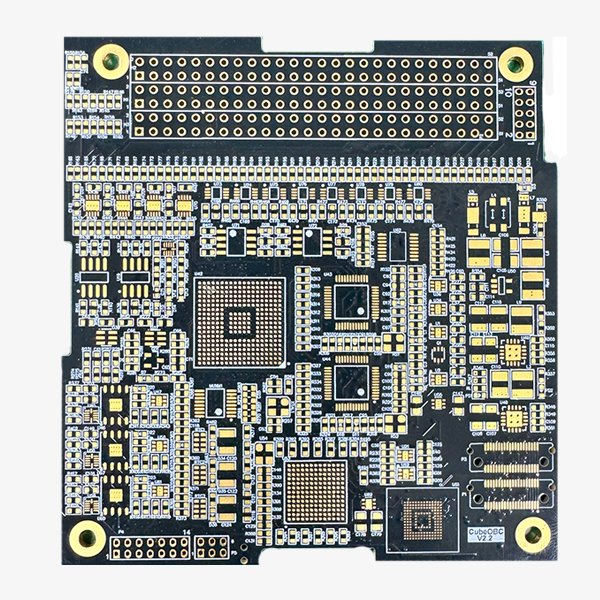

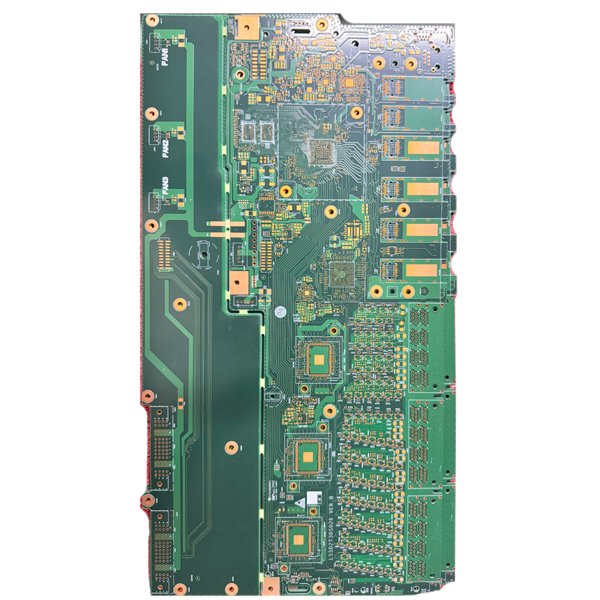

This high-performance PCB delivers exceptional reliability for critical aeronautical communication systems. Featuring up to 24 layers with premium materials like CEM-3 and High CTI Halogen-Free FR4, this board offers superior thermal stability and signal integrity. Ultra-precise trace widths of 0.05mm and advanced drilling capabilities, including blind/buried vias, ensure optimal component density and signal routing.

Key Features:

Professional-grade copper thickness options from 1/3 OZ to 5/5 OZ

Large working panel size: 760mm × 660mm

Precision drilling down to 0.15mm with tight tolerances

Multiple finishing options including ENIG and Flash Gold

Comprehensive testing: Impedance, Flying Probe, and Low Resistance

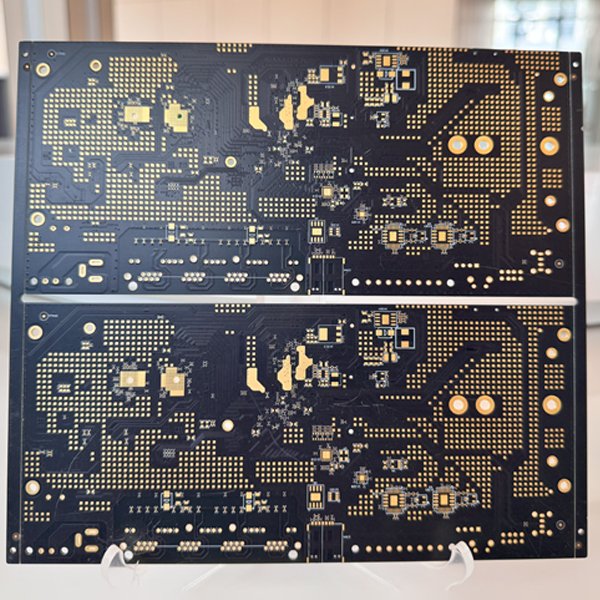

IPC-A-600G compliant with max 0.5% warp and twist

Ideal for mission-critical aeronautical communication systems requiring exceptional reliability and performance.

Technique Capability:

Layer Count | From 2L to 24L |

Material | CEM-3. FR4. High High CTI Halogen Free |

Thickness | Inner: 0.1mm Outer. 0.3-3.5mm |

Copper Thickness & UL | 1/3 OZ, H/H OZ, 1/1 OZ, 2120Z, 3/30Z, 4/40Z, 5/50Z |

Working Panel Size | 760mm x 660mm |

Drill Capability | Blind//buried via, Semi-drill, Finished hole size: 0.15mm -6.5mm; NPTH: ±O.05mm PTH: ±0.075mm Hole Position: ±0.075mm |

Trace width/space | 0.05/0.05mm |

Finishing | OSP. LF HAL, Flash Gold. ENIG. Immersion Tin. (Gold Plating) (Carbon Ink) |

Solder mask | Thickness >= 10um (UV Solder Mask) |

Profile & Tolerance: | Punch, Route, V-CUT; ± 0. 1mm |

Peelable Mask: | Thickness >= 0.3mm |

Warp & Twist: | IPC-A-600G . Max. 0.5% |

Functional Test: | IMPEDENCE, OPEN/SHORT, FLYING PROBE. LOW RESISTANCE TEST; |